Professionals seek validation and credit for their competence and reliability in the ever-changing industrial maintenance world. The Machinery Lubrication Engineer (MLE) certification is one such prestigious title.

Dear CRE Philippines Family and Valued Clients,

As we gather to celebrate our 15th anniversary, I am overcome with a deep sense of pride and gratitude for the remarkable journey of CRE Philippines. This milestone is a testament to the unwavering support and dedication of each member of the CRE family and the trust placed in us by our esteemed clients.

Oil analysis is a potent ally for those entrusted with the upkeep and improvement of machinery in diverse industrial environments.

The significance of proper lubrication must be balanced in machinery maintenance and reliability. Well-lubricated machinery ensures optimal performance, minimizes wear and tear, and prolongs the lifespan of critical components.

Maintenance teams play a crucial role in ensuring the seamless operation of manufacturing facilities.

In the realm of industrial machinery maintenance, ensuring optimal performance and longevity is of paramount importance.

Oil analysis is a formidable tool in predictive and proactive maintenance, providing invaluable insights into the health and condition of machinery. For maintenance professionals and enthusiasts keen on harnessing the full potential of this diagnostic approach, attention to three often overlooked aspects is paramount: providing accurate details, ensuring bottle integrity, and maintaining optimal sampling conditions.

Precision and accuracy have become paramount in the ever-evolving landscape of industrial machinery maintenance. Maintenance professionals rely on data-driven decision-making to ensure optimal performance and durability of machinery.

In industrial machinery and equipment, the pursuit of reliability and optimal performance is paramount. Maintenance professionals have undertaken a quest for excellence by exploring various Predictive Maintenance Techniques. Among these techniques, ultrasound and vibration analysis emerge as indispensable tools. This blog will delve into the considerations, recommendations, and best practices for harnessing the potential of Predictive Maintenance Techniques in lubricant maintenance.

In the machinery maintenance and lubrication world, ensuring the optimal performance and longevity of mechanical components is a constant pursuit.

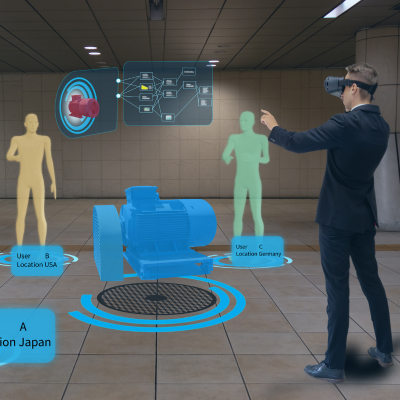

In the ever-evolving world of industrial machinery and equipment maintenance, one can't help but notice the duality between tradition and innovation. At the heart of this juxtaposition is the age-old concept of tribal knowledge and age-old wisom, which has long been an essential part of the maintenance industry.

In today's fast-paced industrial landscape, machinery plays a pivotal role in ensuring smooth operations and consistent productivity, with the efficiency and longevity of machinery relying on various factors, including proper lubrication.

Lubrication is a fundamental aspect of machinery maintenance, ensuring that the suitable lubricant is applied in the correct quantity and at the appropriate intervals.

In today's fast-paced industrial landscape, where facilities are running on leaner staff and striving for increased operational efficiency, the significance of quality data from oil analysis has surged.

The Philippines is making strides toward enhancing maintenance strategies in reliability-centered maintenance. A critical element in this pursuit is understanding when oil has reached its temperature limit.

Mobile equipment plays a crucial role in industries such as construction, mining, agriculture, and transportation, where maintaining peak performance is vital to maximize productivity and minimize downtime.

Predictive maintenance techniques play a pivotal role in ensuring industrial machinery's reliability and extended lifespan.

Welcome to our comprehensive guide on developing an effective lubrication program. Whether you are a maintenance professional, an engineer, or an industry enthusiast, this article aims to provide valuable insights and practical tips for creating a successful lubrication program.

Amid today's evolving industrial landscape, where machinery is central to manufacturing and transportation sectors, the significance of optimal machine functionality cannot be overstated.

In today's advancing technological landscape, the manufacturing industry faces a significant challenge - the skills gap.