Lubrication is required for each piece of machinery with moving components. Lubrication is essential, but it may be a difficult task. This article seeks to answer some of the most often asked concerns regarding lubrication so you can choose the correct lubricant, not simply the cheapest or fastest. For a consultation, you can contact our Engineers here.

Important Terms in Tribology

To make the best decisions on lubrication, you must first grasp the terms. The following are some of the terms commonly used in tribology:

- Metal-to-metal contact - this is a circumstance in which no lubricant is left in a bearing or other application. This should always be avoided.

- Shear stability - this refers to an oil's ability to withstand a change in viscosity produced by mechanical stress.

- NLGI Consistency - The consistency of a grease determines how hard or soft it is. The numbers range from 000 to 6

- Runout - is a grease's or oil's capacity to withstand higher temperatures, which tend to make lubricants less viscous.

- Weight - this also relates to how freely oils can flow at a given temperature

- Kinematic viscosity - is the internal resistance to the flow of a fluid under gravitational forces.

- Viscosity - The viscosity of an oil or grease specifies how thick or hard it is to flow. The higher the viscosity, the greater the flow resistance.

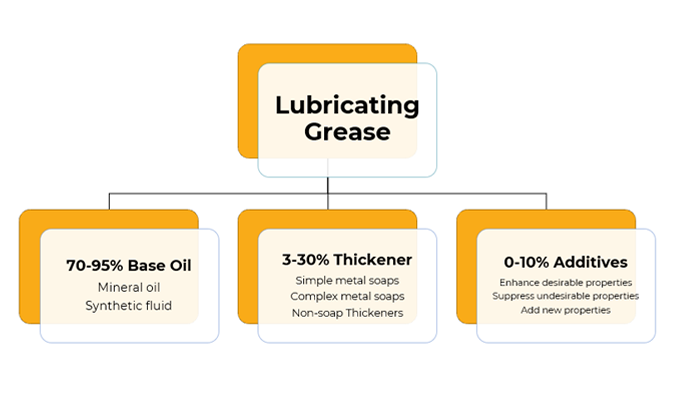

Ingredients of Grease

Many people are unaware that greases are just oils thickened with thickeners. Typically, a thickener is made up of molecules that work as a sponge to keep the oil in place. Each thickener type has its own set of benefits and drawbacks, particularly in terms of pumpability, heat resistance, and water resistance.

Purpose of Lubricants

Lubricants have a wide variety of purposes that include regulating the following:

- Friction (lubricants reduce heat generation and energy consumption)

- Wear

- Corrosion due to corrosive substances

- Contamination

- Temperature (lubricants can absorb and transfer heat)

- In the case of hydraulics, lubricants can also be used to transmit power.

All these imply that you must first determine the particular obstacles your application presents before selecting a lubricant. Choose lubricants that are properly labeled with instructions on how to use them and under what conditions they should be used.

Lifespan

Lubricants have a set lifespan and must be replenished after that time has passed. Failure to do so can cause runout, metal-on-metal contact, bearing destruction, and other problems. You can track the lifespan of a lubricant by monitoring the operating temperature of your equipment. At 168 degrees F, a lubricant that would ordinarily last a month at 150 degrees F will barely last two weeks.

Digital calibration instruments that can provide thermal imaging, as well as vibration analysis, are ideal for heat tracking. Some digital systems make this straightforward, but it's easy to overlook this in smaller businesses where records are still kept by hand. At least one member of your team should be in charge of lubrication, as well as ensuring that correct records are kept.

User-Friendliness

The technique of application will be determined by the equipment you have. An aerosol lubricant may be sufficient in some cases, such as an easy-to-reach hinge. A continuous dispenser may be the ideal option for chains that require constant lubrication. If you're buying lubricants from a reliable supplier, talk to one of their experts.

Cost

A food-processing plant may opt to use mineral oil on transport chains because it's cheap and food-safe. Plain mineral oil has a number of disadvantages that outweigh the low cost. It may have poor runout characteristics, attract contaminants to form an abrasive paste or drip to create an unsafe working environment. Smart businesses spend as much time thinking about lubrication as they do about the types of equipment they purchase.

Grease Analysis

Most bearings use grease but many organizations do not take advantage of the benefits a grease analysis can do for their predictive maintenance initiatives. Talk to our machinery lubricant consultants and analysts to know more about the wealth of information you can get from this test and how to conduct sampling safely.

Source: machinerylubrication.com