Welcome to our comprehensive guide on developing an effective lubrication program. Whether you are a maintenance professional, an engineer, or an industry enthusiast, this article aims to provide valuable insights and practical tips for creating a successful lubrication program.

By following the three essential steps of assessment, planning, and execution, you can optimize machinery performance, minimize downtime, and extend the lifespan of your equipment. Explore each stage and the crucial elements contributing to a robust lubrication program.

Step 1: Analyzing Current Practices

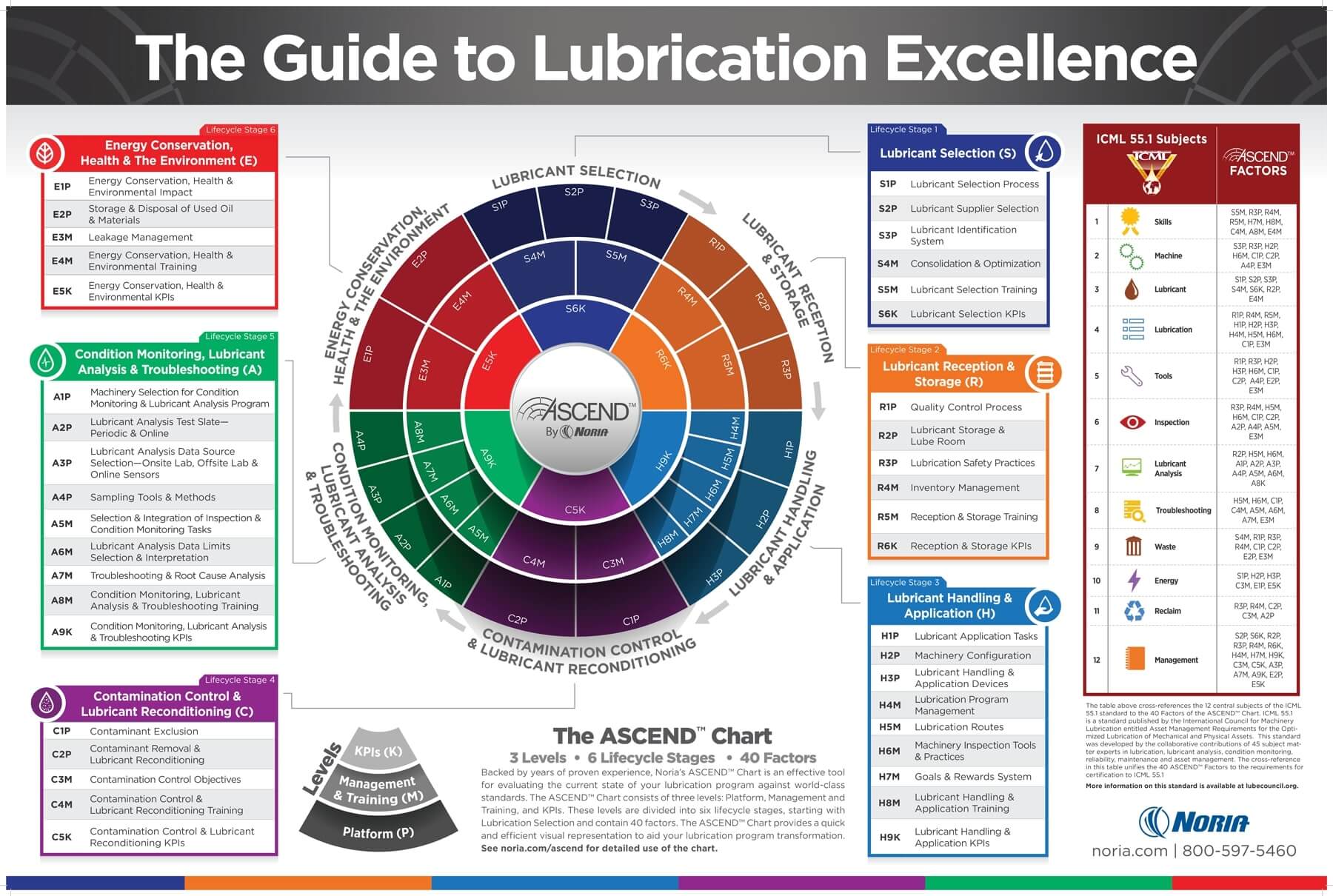

Before embarking on any improvements, assessing the existing lubrication practices within your organization is crucial. By conducting a thorough assessment, such as ASCEND Benchmarking, you can identify gaps, weaknesses, and areas of improvement that will form the foundation of your lubrication program.

ASCEND Benchmarking is a comprehensive program that offers both online and onsite set-up for assessments. It is intended to examine your present lubrication program, compare it to industry best practices, and provide a roadmap to help you achieve lubrication excellence. This step utilizes a 500-point assessment survey that measures the current state of your program and employs the ASCEND Method to provide recommendations for improvements across the 40 critical elements of a lubrication program.

The process unfolds over three days:

- Day 1: Facility walkthrough and stakeholder interviews are conducted to understand your current lubrication practices and engage with key personnel.

- Day 2: Offsite, the gathered information is compiled and analyzed, and a detailed report is developed based on the findings.

- Day 3: The report and a half-day awareness training on lubrication are presented to plant stakeholders. This session helps increase awareness and knowledge among the team members involved.

This step delivers several valuable outcomes:

- Executive Summary

- SWOT Analysis

- Compliance Level

- Lubrication Program Manager (LubePM) Access

- Cost-Benefit Analysis

- Assessment of 40 Elements

By integrating ASCEND Benchmarking into your analysis of current practices, you can understand your lubrication program's strengths and weaknesses while obtaining a roadmap for achieving lubrication excellence based on industry best practices.

Step 2: Developing a Strategy

Based on the assessment findings, the next step is to develop a comprehensive plan that aligns with your organization's objectives. This plan will involve a strategic approach to optimize your lubrication activities and enhance efficiency.

This step focuses on eliminating failure by designing, standardizing, and specifying step-by-step procedures for each lubricated asset. The goal is to create a database that provides improvement recommendations, collected data, detailed work procedures, consolidated lubricant recommendations, and hardware modification suggestions. This engineered approach ensures that even new technicians or personnel can follow and perform the lubrication procedures accurately and consistently.

Furthermore, in this step, we introduce Route Optimization to streamline and enhance the efficiency and effectiveness of your lubrication program. This optimization saves time, allowing your team to focus more on strategic tasks. The process involves streamlining wrench time, inspections, lubrication, and oil sampling tasks, resulting in an optimized workflow that maximizes uptime and minimizes unnecessary delays.

Besides these program engineering initiatives, the following aspects should be incorporated into your lubrication strategy:

- Establish Standards

- Schedule

- Centralized Lubrication Management (CLM) System

- Storage and Handling

By combining Program Engineering with these strategic elements, you can ensure a well-structured lubrication plan that optimizes your lubrication activities, enhances efficiency, and reduces the risk of failures or disruptions.

Step 3: Implementing the Program

With a well-defined plan, it's time to execute and implement your lubrication program. This stage involves applying lubrication procedures, ongoing monitoring, and continuous improvement efforts.

Execution: Train your maintenance team on the new lubrication procedures and ensure they follow them. Implement proper lubrication techniques, including appropriate application methods, correct lubricant quantities, and adherence to specified intervals.

Monitoring: Track the effectiveness of the lubrication program through condition-based monitoring techniques, such as oil analysis and equipment inspections. Analyze the results to identify potential issues, lubricant degradation, or the need for adjustments to the program.

Continuous Improvement: Establish a feedback loop and encourage collaboration among the maintenance team to share insights and lessons learned. Use the information to refine lubrication procedures, optimize lubricant selection, and improve program effectiveness.

KPIs: Define KPIs to measure the success of your lubrication program. Track metrics such as equipment uptime, reduction in maintenance costs, lubricant consumption, and equipment reliability to test program performance.

Conclusion

Developing a robust lubrication program is a crucial step in ensuring the reliability and longevity of your equipment. Following the assessment, planning, and execution stages outlined in this guide, you can optimize machinery performance, minimize downtime, and improve operational efficiency.

A well-maintained and lubricated machine forms the foundation of a successful operation. Investing in a comprehensive lubrication program allows you to reap the rewards of improved reliability, reduced maintenance costs, and enhanced productivity.

At CRE Philippines, we provide expert guidance and consultancy services to take your lubrication program to the next level. With our extensive experience and expertise, we can assist you in developing a tailored lubrication program that aligns with your specific needs and goals. Our consultancy services offer comprehensive support, including assessing your current practices, designing an effective lubrication strategy, and implementing sustainable improvements.

By partnering with CRE Philippines, you gain access to a team of professionals dedicated to optimizing your maintenance practices and driving operational excellence. We understand the importance of a well-designed lubrication program in maximizing equipment reliability and performance.

Take advantage of this opportunity to enhance your maintenance practices and unlock the full potential of your equipment. Contact us today to learn more about our services and how CRE Philippines can help you achieve optimal lubrication program development.

Start your journey toward improved equipment reliability and performance now with CRE Philippines’ Lubrication Program Development. Invest in the future of your organization and ensure long-term success.

Source:

Farless, P. (2023, April). Lubrication Program Development: Assess, Plan and Execute. Machinery Lubrication. https://www.machinerylubrication.com/Read/32321/lubrication-program-development-assess%2c-plan-execute