In the machinery maintenance and lubrication world, ensuring the optimal performance and longevity of mechanical components is a constant pursuit.

One of the critical aspects of achieving this goal involves monitoring and managing the contaminants in lubricating oils. Insoluble contaminants, such as dirt, wear debris, and various particulates, can impact the efficiency and durability of machinery. Thus, accurate and efficient methods for measuring these contaminants are essential for maintenance professionals and engineers. In this article, we delve into the rationalization of laboratory tests used to measure insoluble contaminants in lubricating oil, exploring two prominent methods: gravimetric analysis and the centrifugal method.

Gravimetric Analysis

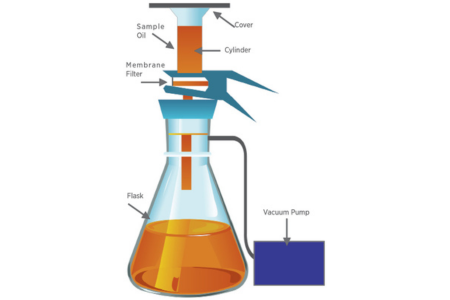

Gravimetric analysis, a well-established laboratory technique, involves the measurement of the mass of a substance to determine its concentration. In the context of measuring insoluble contaminants in lubricating oils, this technique entails collecting a representative sample of the oil and filtering out the solid contaminants. These contaminants are then collected on filter paper, dried, and weighed. The increase in the weight of the filter paper reflects the amount of insoluble contaminants present in the oil sample.

While gravimetric analysis has been a staple in the field for decades, it has limitations. The process is time-consuming and labor-intensive, requiring meticulous handling to ensure accurate results. Furthermore, the technique might need to be more sensitive to detect smaller particles, which can still impact machinery performance despite their size. As industries strive for greater efficiency and precision, alternative methods have emerged to address these shortcomings.

Centrifugal Method

The centrifugal method offers a more streamlined and efficient way of measuring insoluble contaminants in lubricating oils. This method uses centrifugal force to speed up the separation of solid contaminants from the oil. The principle is simple: when a sample of oil is subjected to high centrifugal forces, the heavier solid particles move outward, while the cleaner oil remains closer to the center.

In practice, a centrifuge equipped with a specialized rotor is used for this process. The oil sample is placed in the rotor, then spun at high speeds. As the rotor spins, the solid contaminants migrate toward the outer edges of the rotor, forming a distinct layer. This layer can then be analyzed to determine the level of contamination.

The centrifugal method offers several advantages over traditional gravimetric analysis. It reduces the time required for analysis, allowing maintenance teams to make quicker decisions on machinery maintenance. The centrifugal method can detect smaller particles that might be missed by traditional methods, enhancing the accuracy of the measurements. The process is more automated, reducing the risk of human error and improving repeatability.

Conclusion

In the grand scheme of optimizing machinery performance, the rationalization of laboratory tests for measuring insoluble contaminants in lubricating oil underscores industrial maintenance practices' dynamic and evolving nature. Traditional gravimetric analysis has served the industry, providing valuable insights into contamination levels. But, the industry's thirst for expedited results, heightened sensitivity, and reduced human involvement have paved the way for the ascendancy of the centrifugal method. Each approach carries its strengths, and the selection between them hinges on the particular demands of the industry and the specific machinery under scrutiny.

ForThe centrifugal method emerges as an enticing and pragmatic solution for industries that hold precision and efficiency in high regard; nonetheless, maintaining a harmonious equilibrium between embracing innovative techniques and preserving a robust foundation in well-established practices is paramount. As the industrial landscape continues its dynamic evolution, professionals must stride forward with an open-minded disposition, embracing novel methodologies while still upholding the rich tapestry of knowledge and experience that has shaped the industry thus far.

MachineDiagnostics™ Program

As you embark on the journey to refine your machinery maintenance strategies, consider harnessing the power of advanced technology and expertise through CRE Philippines' MachineDiagnostics™ Program. This program, designed to empower industries with cutting-edge reliability solutions, offers various benefits tailored to your machinery management needs. From precise oil analysis to comprehensive diagnostics, MachineDiagnostics™ equips you with the tools to make informed decisions that optimize machinery performance and prolong operational lifespans. Discover more about the program's offerings and how it can revolutionize maintenance practices by contacting us.

Source:

Molla, H. J. (2022, August). Rationalization of Lab Tests for Measurement of Insoluble Contaminants in Lube Oil. Machinery Lubrication. https://www.machinerylubrication.com/Read/32184/rationalization-of-lab-tests-for-measurement%20of-insoluble-contaminants-in-lube-oil