Precision and accuracy have become paramount in the ever-evolving landscape of industrial machinery maintenance. Maintenance professionals rely on data-driven decision-making to ensure optimal performance and durability of machinery.

One critical aspect of this process is oil analysis, which allows for insights into the condition of machinery components and lubricants. As we delve into the world of oil analysis, we must recognize the pivotal role that oil sample bottles play in this process. This blog series explores how advanced oil sample bottles transform how maintenance professionals approach machinery health assessment.

Traditional oil sample bottles were once mere vessels to hold oil samples for analysis. But advancements in materials, design, and manufacturing have led to the emergence of advanced oil sample bottles that offer enhanced functionalities. These bottles are designed to preserve the integrity of oil samples, ensuring that the collected data reflects the condition of the machinery. Airtight seals, tamper-evident closures, and integrated labels for clear sample identification are some features that distinguish these advanced bottles from their predecessors. Maintenance professionals can now trust that the collected samples represent the machinery's health.

Source: Anatomy of a Representative Oil Sample: Part 1 - Sample Bottles (machinerylubrication.com)

Source: Anatomy of a Representative Oil Sample: Part 1 - Sample Bottles (machinerylubrication.com)

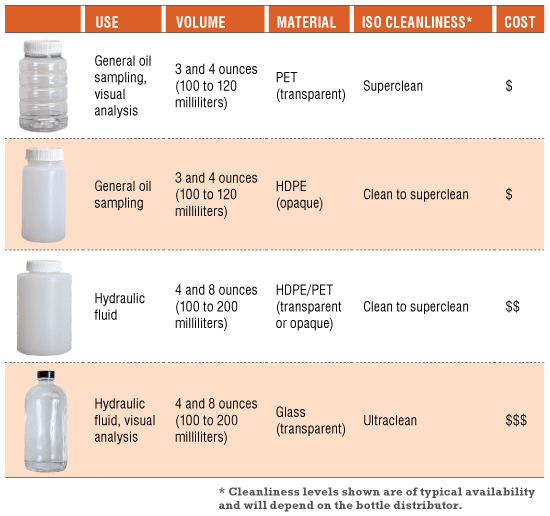

Cleanliness

One of the often-overlooked factors in oil analysis is the sample bottles' cleanliness. Contaminated bottles can introduce foreign particles and chemicals into the samples, skewing the analysis results. Advanced oil sample bottles address this concern using high-quality materials resistant to leaching and contamination. Additionally, these bottles are designed to minimize the risk of external contaminants entering the bottle during sample collection, storage, and transportation. This attention to bottle cleanliness contributes to the reliability and accuracy of the analysis process.

Source: Anatomy of a Representative Oil Sample: Part 1 - Sample Bottles (machinerylubrication.com)

Source: Anatomy of a Representative Oil Sample: Part 1 - Sample Bottles (machinerylubrication.com)

Material and Size

The choice of material and size for oil sample bottles can impact the quality of the collected samples. Advanced bottles are made from materials inert to the oil being analyzed, ensuring no interaction between the bottle and the sample. This prevents any alteration of the sample's properties over time. Furthermore, these bottles come in various sizes, catering to many machinery types and oil volumes. A proper match between the bottle size and the importance of the oil to be sampled is crucial for obtaining representative data.

Source: Anatomy of a Representative Oil Sample: Part 1 - Sample Bottles (machinerylubrication.com)

Source: Anatomy of a Representative Oil Sample: Part 1 - Sample Bottles (machinerylubrication.com)

Collection

Collecting oil samples might seem straightforward, but it requires a meticulous approach to ensure accurate results. Advanced sample bottles often come with built-in features that simplify the sampling process. Some bottles include vacuum-assist options that help draw in oil from the machinery, reducing the risk of external contaminants entering the bottle. Proper sampling techniques, such as sampling from the correct location and avoiding cross-contamination, are also essential for reliable analysis outcomes. Maintenance professionals can improve the precision of their machinery health assessments by using advanced oil sample bottles and following best practices.

Conclusion

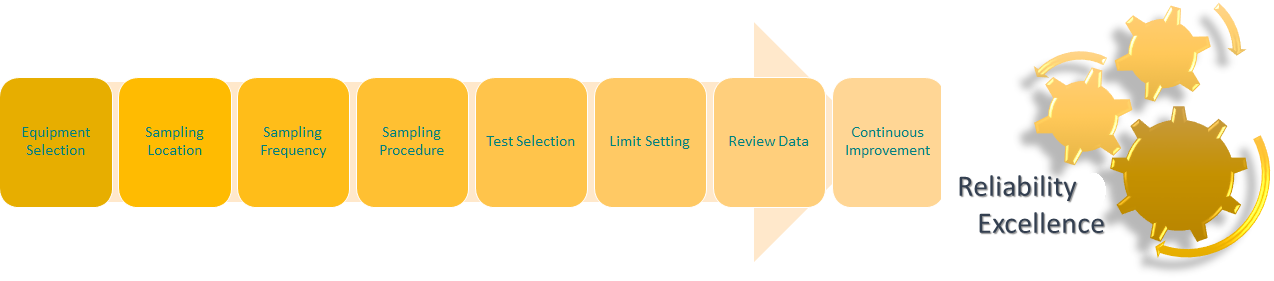

As machinery maintenance continues its evolution towards data-driven precision, the role of advanced oil sample bottles takes center stage. Part one of this comprehensive blog series has highlighted the indispensable significance of these bottles in ensuring a realm of accurate and dependable oil analysis. Our exploration ventured into their innovative features, emphasizing the profound impact of bottle cleanliness, the meticulous selection of materials and sizes, and the intricate artistry of proper sample collection. But let's remember; this is the prologue to our voyage into the realm of advanced oil sample bottles.

As we await the next chapter of this enlightening series, seize an opportunity to transform your machinery maintenance approach. Take a step forward with the CRE Philippines’ MachineDiagnostics™ Program, which incorporates cutting-edge oil analysis practices. Explore the program by contacting us and embark on a journey to amplify your maintenance prowess. Your machinery's future awaits—will you rise to meet it?

Source:

Fitch, B. (2014, February). Anatomy of a Representative Oil Sample: Part 1 - Sample Bottles. Machinery Lubrication. https://www.machinerylubrication.com/Read/29662/oil-sample-bottles