In today's fast-paced industrial landscape, machinery plays a pivotal role in ensuring smooth operations and consistent productivity, with the efficiency and longevity of machinery relying on various factors, including proper lubrication.

As industries strive for operational optimization, the significance of oil analysis laboratories in maintaining machinery health cannot be overstated. This article is tailored to maintenance professionals, engineers, plant managers, and anyone engaged in the maintenance and upkeep of industrial machinery, whether seasoned experts or newcomers, aiming to explain the world of oil analysis laboratories, their vital importance in machinery maintenance, and strategies to uphold the integrity of the invaluable data they furnish.

Ensuring Accurate Oil Analysis Insights

In an era defined by the paramount importance of data, accuracy and reliability take center stage, echoing across various industries. Within this landscape, oil analysis data emerges as a pivotal element, shedding light on the intricate condition of machinery components and the efficacy of lubrication systems. But the foundation of trust upon which this data stands is constructed upon a bedrock of meticulous considerations.

The cornerstone of robust oil analysis lies in the meticulous art of sampling techniques. This process initiates the journey from machinery to the laboratory to encapsulate an accurate representation of the lubricant's condition within the equipment. Precise sampling necessitates a harmonious orchestration of factors—location, timing, and equipment selection—to encapsulate a snapshot of the machinery's inner workings.

Yet, another figure steps onto the stage in this delicate dance between precision and insight: contamination control. An inconspicuous element, even minor contaminants within samples, can wield power to warp results, leading to conclusions that diverge from reality. Thus, adhering to the tenets of contamination control becomes pivotal—strategies to preserve the sanctity of samples, mitigating the risks of skewed data interpretations.

Amidst these intricacies, the linchpin of consistency emerges as a guiding principle. Standardized procedures governing the entire lifecycle of oil analysis, from sample collection to handling and analysis, lay the groundwork for a reliable framework. By adhering to these procedures, industries forge a path toward uniformity and comparability in results, elevating the trustworthiness of the insights drawn from the data.

Real-Time In-House Oil Analysis Benefits

Before, we discussed the distinctive aspects of In-House vs Commercial Lab oil analysis, scrutinizing the benefits and challenges tied to both approaches. Let's delve further into the transformative world of in-house oil analysis—a real-time wellspring of actionable insights that underpin effective machinery maintenance. As we embark on this exploration, it's essential to recognize that the choice between in-house and commercial labs can influence the approach to in-house analysis.

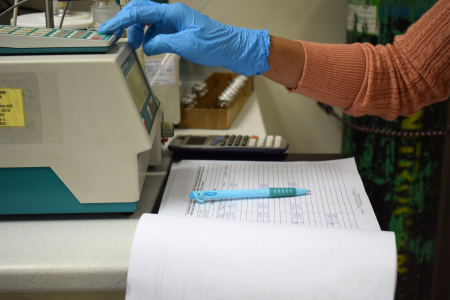

The realm of laboratory analysis plunges deep into the intricacies of machinery health, scrutinizing components and lubrication systems with meticulous precision. Yet, a dynamic paradigm shift emerges with the concept of in-house oil analysis. This approach unfolds as an immediate, real-time source of insights facilitated by the strategic deployment of portable instruments. These instruments are adept at assessing lubricant conditions at the machinery's site, injecting a new level of urgency into decision-making processes. This transformation is a beacon of innovation in machinery maintenance, redefining the landscape.

The primary advantage of in-house analysis is its capacity to speed up maintenance response. Real-time detection of potential issues empowers swift, informed decision-making. This vigilance enables maintenance teams to trigger immediate actions, thwarting adversities and sidestepping catastrophic failures that might arise from delayed interventions. The availability of vital data on-demand facilitates the precise application of remedies, reducing downtime and enhancing operational continuity.

Besides its immediate impact, in-house analysis brings significant fiscal implications. This approach saves time and cost by eliminating the need for sample transportation to external laboratories. The proximity-driven method streamlines logistical complexities and truncates the time lag between data collection and interpretation. This expedited transition from observation to strategic implementation fosters efficiency. Furthermore, this cost-effectiveness resonates long-term, as reduced downtime and optimized maintenance scheduling translate into sustainable operational efficiencies.

As the rhythm of frequent in-house analysis takes root, a continuous monitoring loop emerges, channeling data from machinery to analysis instrument and back again. This iterative process lays the foundation for proactive maintenance planning, allowing anticipatory measures driven by real-time data trends. Such responsiveness marks a departure from conventional maintenance practices, permitting fine-tuning of lubrication routines and machinery configurations and amplifying the efficiency of the machinery ecosystem.

Choosing a Reliable Oil Analysis Lab

When navigating the landscape of oil analysis laboratories, the pillars of accuracy and reliability stand as non-negotiable requisites. The selection of a laboratory partner can be a transformative determinant in the quality of insights gleaned. As industries seek dependable guidance to bolster their machinery maintenance, a strategic partnership with a reputable laboratory emerges as a beacon of reliability and precision. Several critical steps come to the fore to navigate this terrain, ensuring that the chosen laboratory is a trustworthy custodian of data-driven wisdom.

Amidst this pursuit, the foundational step of accreditation and certification becomes a guiding light. It is imperative to seek laboratories that hold accreditation from relevant industry bodies. This seal of approval is a testament to the laboratory's adherence to standardized procedures and commitment to upholding a Pinnacle of competence. In a world where accuracy is paramount, partnering with an accredited laboratory establishes the groundwork for dependable analysis outcomes.

Furthermore, the quality control processes embraced by the laboratory become a pivotal aspect of evaluation. A reliable laboratory should wield a robust arsenal of stringent quality assurance measures. These processes act as sentinels, safeguarding against potential discrepancies and lending more validation to the analysis results. Inquiries into the laboratory's approach toward quality control unveil their commitment to precision and their dedication to offering insights grounded in verifiable accuracy.

As the evaluation process unfurls, the factor of experience and expertise assumes a central role. The longevity of a laboratory in the field and its track record of accurate predictions and actionable recommendations are telling indicators of its worth. The seasoned expertise accrued over time transforms into an invaluable asset, leading to insights that are not data points but instead informed counsel. When partnering with a laboratory, the cumulative wisdom amassed through years of practice contributes to the caliber of insights extended, becoming a cornerstone of trustworthy decision-making.

ASTM Crosscheck Reminder

Accurate lubrication is pivotal for seamless productivity in the dynamic realm of industrial machinery. Acknowledging the vital importance of precise machinery health assessment, the ASTM Crosscheck approach becomes crucial. This practice involves scrutinizing commercial oil analysis laboratories using ASTM standard methodologies, adding an extra layer of confidence in the accuracy of results.

Professionals have trusted their chosen oil analysis laboratories for accurate insights. But the intricacies of machinery maintenance call for a cautious stance. By employing the ASTM Crosscheck reminder, which involves ensuring laboratories adhere to ASTM testing standards, one can reinforce the reliability and consistency of results.

When interacting with commercial laboratories, a simple inquiry about their participation in the ASTM Crosscheck approach and other quality-control accreditations can provide valuable insights. To assure you that a laboratory's performance is at par with other laboratories anywhere in the world, ask if your laboratory participates in the ASTM International Interlaboratyr Crosscheck program (ILCP). Consistency in ASTM testing methodologies across labs is vital to minimize discrepancies. By integrating the ASTM Crosscheck reminder into your maintenance approach and fostering open dialogue with laboratories, you can establish confidence in the accuracy of insights received, enhancing adequate machinery upkeep.

Conclusion

Oil analysis laboratories emerge as indispensable allies in pursuing optimal machinery performance in industrial machinery maintenance. The insights from oil analysis data serve as guiding lights, steering maintenance decisions, mitigating downtime, and elongating equipment lifespans. Whether through in-house analysis or commercial laboratory services, the bedrock of effective machinery maintenance rests upon data precision.

In a world where efficiency and precision reign supreme, oil analysis laboratories serve as beacons of insight, steering industries toward heightened machinery performance and sustained operational triumphs. Armed with informed decisions backed by precise data, enterprises can unlock the full potential of their machinery, propelling progress forward.

Take the Next Step with CRE MachineDiagnostics™ Program

Embarking on maintenance programs centered around diagnosing incipient machine failures through oil analysis requires careful resource allocation. Thorough planning is essential to ensure that investments yield optimal results.

With CRE Philippines, you can embark on your MachineDiagnostics™ Program via oil analysis, with unwavering support at every juncture. Our program includes a comprehensive seminar, the Machine Wear Analysis Basic (MWAB) Seminar, to equip your team with the best lubrication practices. Our dedicated support team will address your report-related concerns while our proficient, certified Lube Analysts and Machinery Lubrication Consultants offer in-depth explanations and actionable recommendations.

Ready to elevate your maintenance practices? Contact us to explore how CRE Philippines' MachineDiagnostics™ Program can revolutionize your machinery maintenance journey.

Source:

Cash, W. (2017, August). Why You Should Crosscheck Your Oil Analysis Lab. Machinery Lubrication. https://www.machinerylubrication.com/Read/30873/oil-analysis-lab