Precision and accuracy have become paramount in the ever-evolving landscape of industrial machinery maintenance. Maintenance professionals rely on data-driven decision-making to ensure optimal performance and durability of machinery.

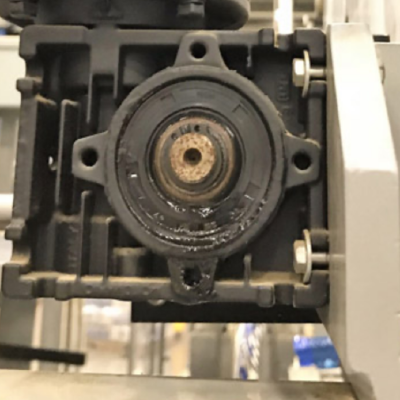

Lubrication is an essential aspect of equipment maintenance and reliability. Minimizing friction, preventing wear and tear, and ensuring smooth machinery operations are critical.

In the machinery maintenance and lubrication world, ensuring the optimal performance and longevity of mechanical components is a constant pursuit.

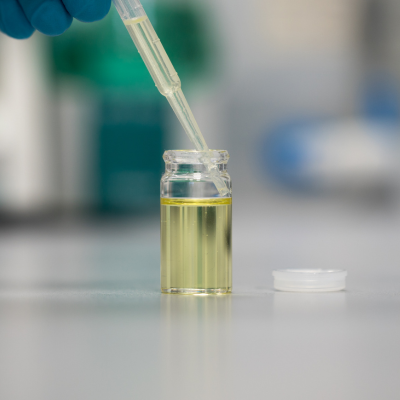

Oil analysis is a critical tool for evaluating the health and performance of equipment. But before an oil analysis report can be generated, it is essential to complete the Sample Information Form (SIF) wholly and accurately.

In today's fast-paced industrial landscape, machinery plays a pivotal role in ensuring smooth operations and consistent productivity, with the efficiency and longevity of machinery relying on various factors, including proper lubrication.

Vibration analysis is a non-destructive testing method that can identify problems with rotating machinery. Analyzing the vibration signals from a machine makes it possible to detect early signs of wear, misalignment, and other issues that could lead to failure.

In today's fast-paced industrial landscape, where facilities are running on leaner staff and striving for increased operational efficiency, the significance of quality data from oil analysis has surged.

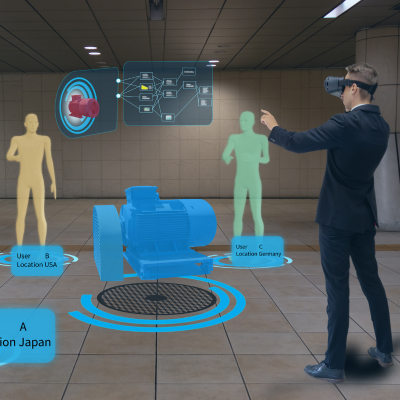

Welcome to the future of lubrication maintenance in Industry 4.0! In today's evolving technological landscape, Artificial Intelligence (AI) is transforming various industries, including lubrication and machinery maintenance.

Mobile equipment plays a crucial role in industries such as construction, mining, agriculture, and transportation, where maintaining peak performance is vital to maximize productivity and minimize downtime.

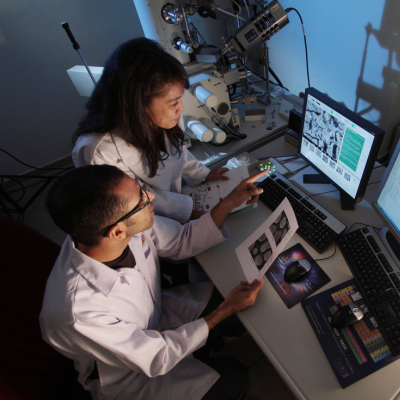

Maintaining industrial equipment is a critical part of ensuring efficient and safe operations. Predictive maintenance techniques using CBM technologies are now widely used to help prevent equipment breakdowns and ensure that machinery functions as expected.

Welcome to our comprehensive guide on developing an effective lubrication program. Whether you are a maintenance professional, an engineer, or an industry enthusiast, this article aims to provide valuable insights and practical tips for creating a successful lubrication program.

Reliability-centered Maintenance (RCM) is used in the maintenance and engineering industries to optimize the reliability and maintainability of equipment, systems, and processes.

In today's advancing technological landscape, the manufacturing industry faces a significant challenge - the skills gap.

Oil analysis reports are critical tools for maintenance professionals responsible for the health and performance of industrial equipment.

In today's fast-paced industrial landscape, businesses rely on the smooth functioning of their machinery and equipment to maintain productivity and meet customer demands.

In today's highly competitive business landscape, companies must find ways to improve t A Guide to Sustainable Continuous Improvement heir performance and efficiency continuously.

The Internet of Things (IoT) concept has gained considerable attention in today's evolving technological landscape.

Machinery lubrication plays a critical role in industrial equipment's optimal performance and reliability.

Dispersancy testing is a crucial technique employed to check the dispersant properties of lubricants. It determines the ability of a lubricant to suspend and disperse contaminants, preventing their accumulation and the formation of harmful deposits.

Oil leaks in machines can be a significant issue, leading to increased wear and tear, decreased efficiency, and even catastrophic failure. This article will explore the causes of oil leaks, their prevention, and methods for detecting them.